Strike Swiftly

Developing Sustainable Maintenance Strategy in Combined Arms Battalion

By LTC Mike Kim, MAJ Nate Bennett, CW3 Jason Amsdell and 1LT Collette Benavidez

Article published on: October 1, 2024 in the Armor Fall 2024 Edition

Read Time: < 13 mins

The mission of the combined arms battalion (CAB) is to close with and destroy enemy forces using fire, maneuver,

and shock effect or to repel their assault by fire and counterattack (Army Techniques Publication 3-90.5,

Combined Arms Battalion). Although this is the singular mission of the CAB, the

demands and requirements put on the organization are great, and personnel challenges [both military occupational

specialty (MOS) and experience shortages] exacerbate the ability to effectively meet mission. While the Region

ally Aligned Readiness and Modernization Model (ReARMM) provides a framework with clear delineation between

train, modernization, and mission windows, in practice, there is overlap where mission sets bleed into each

other creating great demand on battalion formations.

Given this environment, it is paramount that leaders provide a clear and detailed vision that prioritizes and

manages both training and maintenance lines of effort, while clearly articulating areas where risk can be

assumed.

There are many ways to approach this problem set. The purpose of this paper is to convey a way to define the CAB

fight, develop a framework to guide the maintenance enterprise, and provide recommendations to equip battalions

in executing their mission set.

Defining CAB fight

It is commonly said that maintenance builds lethality. In a constrained environment, it is more apropos to state

that lethality requirements drive maintenance. It is the responsibility of the Battalion Commander to clearly

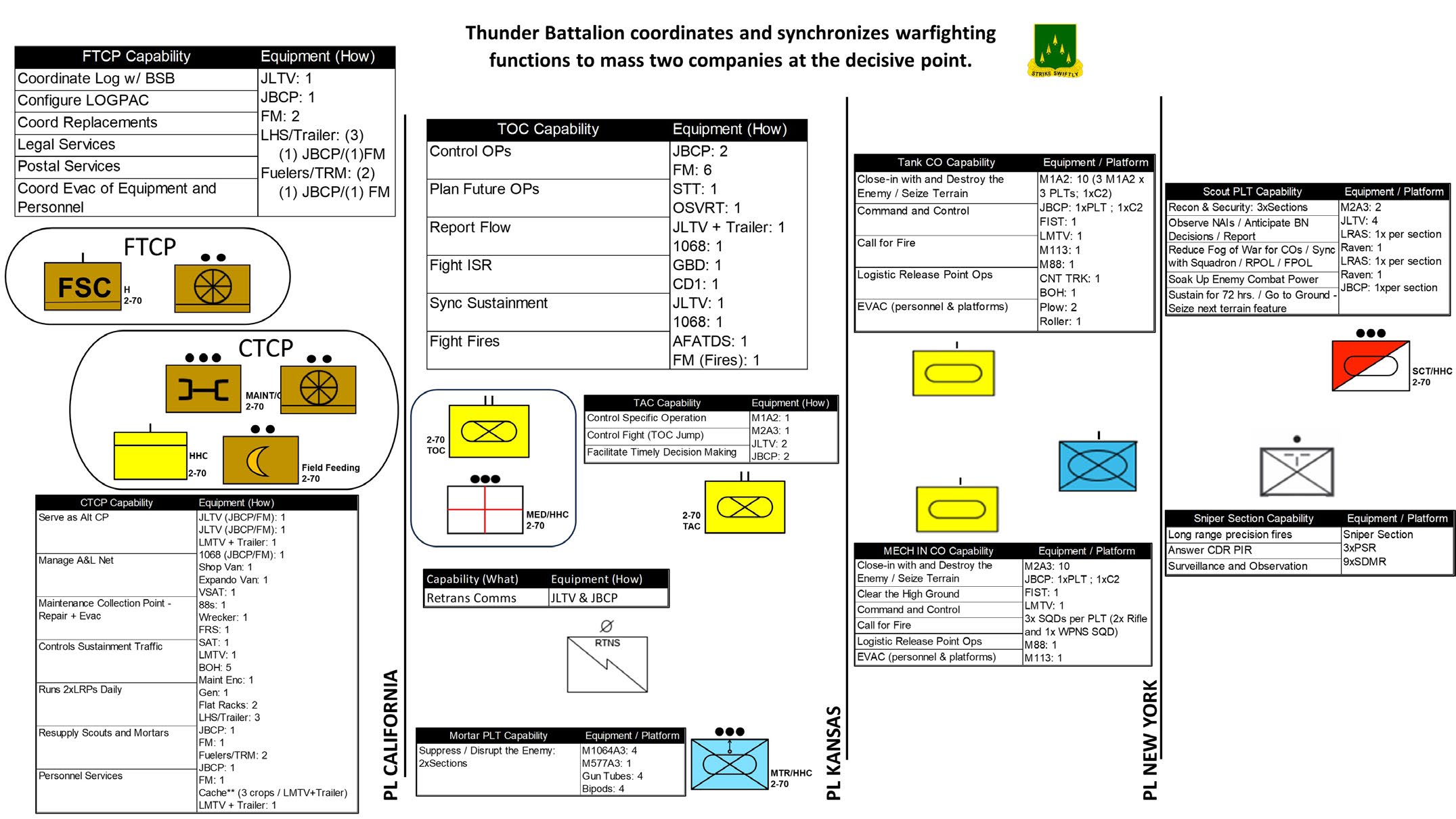

define what lethality means to the formation. The following utilizes an approach used by the 2nd Battalion, 70th

Armor Regiment, 2nd Armored Brigade Combat Team (ABCT), 1st Infantry Division. The overachieving goal of the

2-70 Armor is the following: Thunder Battalion coordinates and synchronizes warfighting functions to mass two

companies at the decisive point.

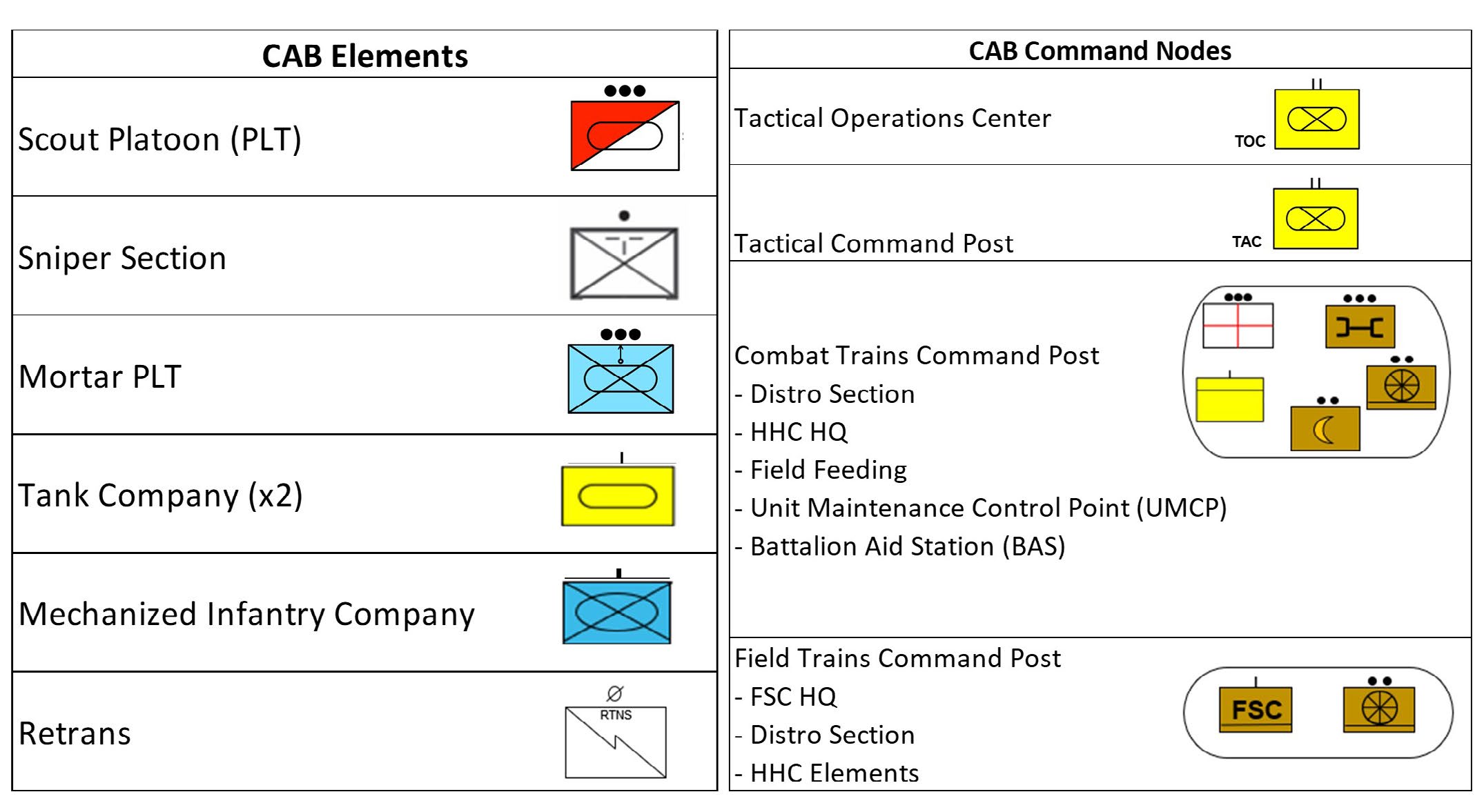

It is a singular statement that guides all battalion efforts. The commander is responsible to define this

guidance based on a clear and defined con struct. The CAB construct can be broken down as depicted in Figure 1

below.

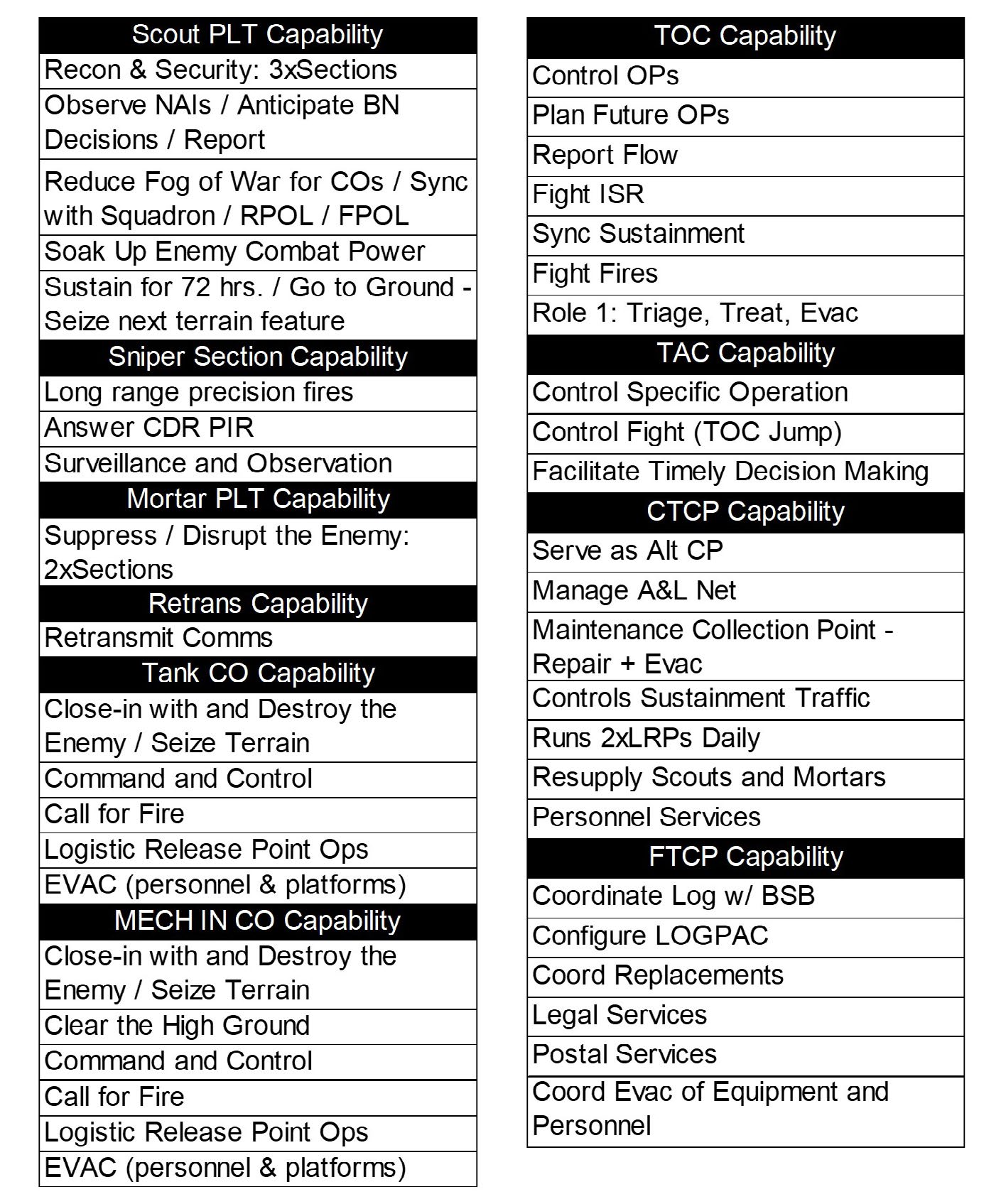

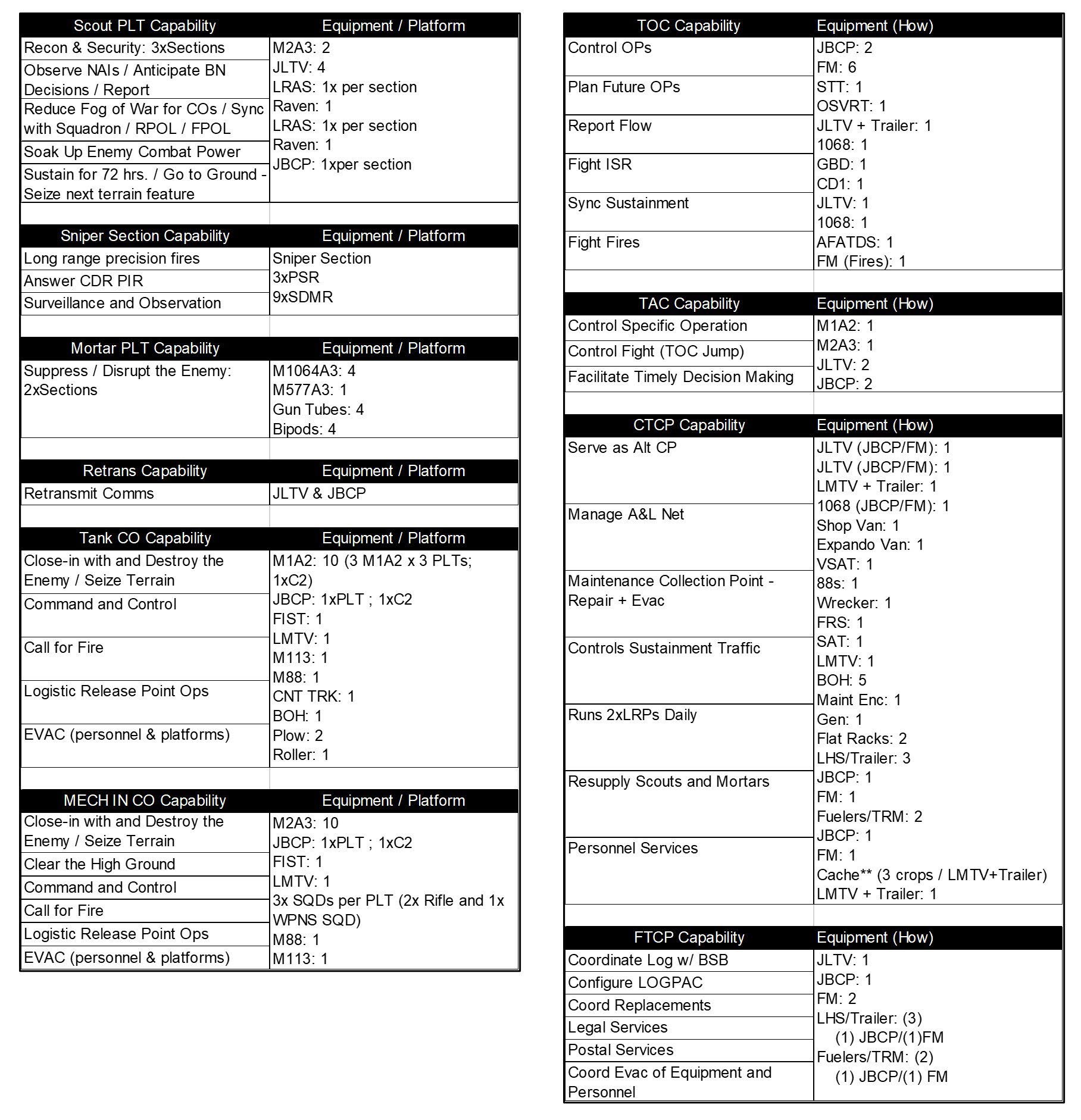

For each of these elements, the lethality capability requirements can be summarized as depicted in Table 1.

Figure 1. Identification of CAB elements and command nodes. (U.S. Army)

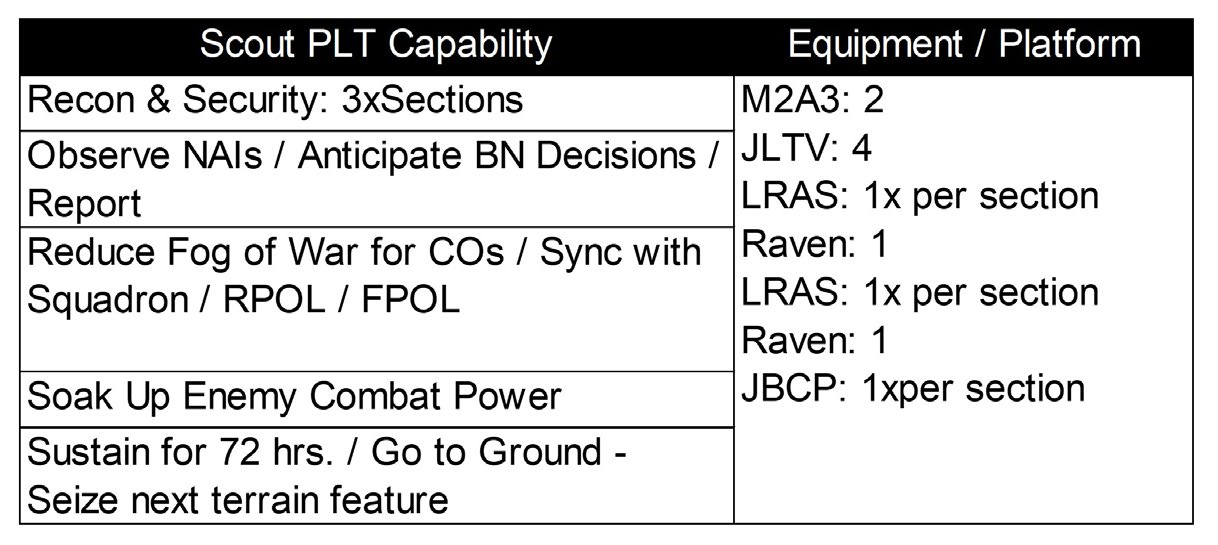

Having listed all the required lethality capabilities, it is important to clearly describe the equipment/platform

needed to meet each capability. This category, which is called the Fight category, is the baseline of equipment

/ platforms needed to deliver the requirement. Although based on the modified tables and organization equipment,

the number requirements are based on a realistic evaluation of the fleet. Leaders who expect every piece of

equipment and platform to be fully mission capable are detached from reality or are being lied to. Using the

Scout PLT as an example, the baseline list of equipment / platforms needed to deliver the capability is depicted

in Table 2. The full list is depicted in Table 3. The overall vision is encompassed in the following compilation

of the figures depicted in Figure 2. This single framework (Figure 2. The Thun-der Fight) focuses the battalion

on both training and maintenance lines of effort.

Where formations fit

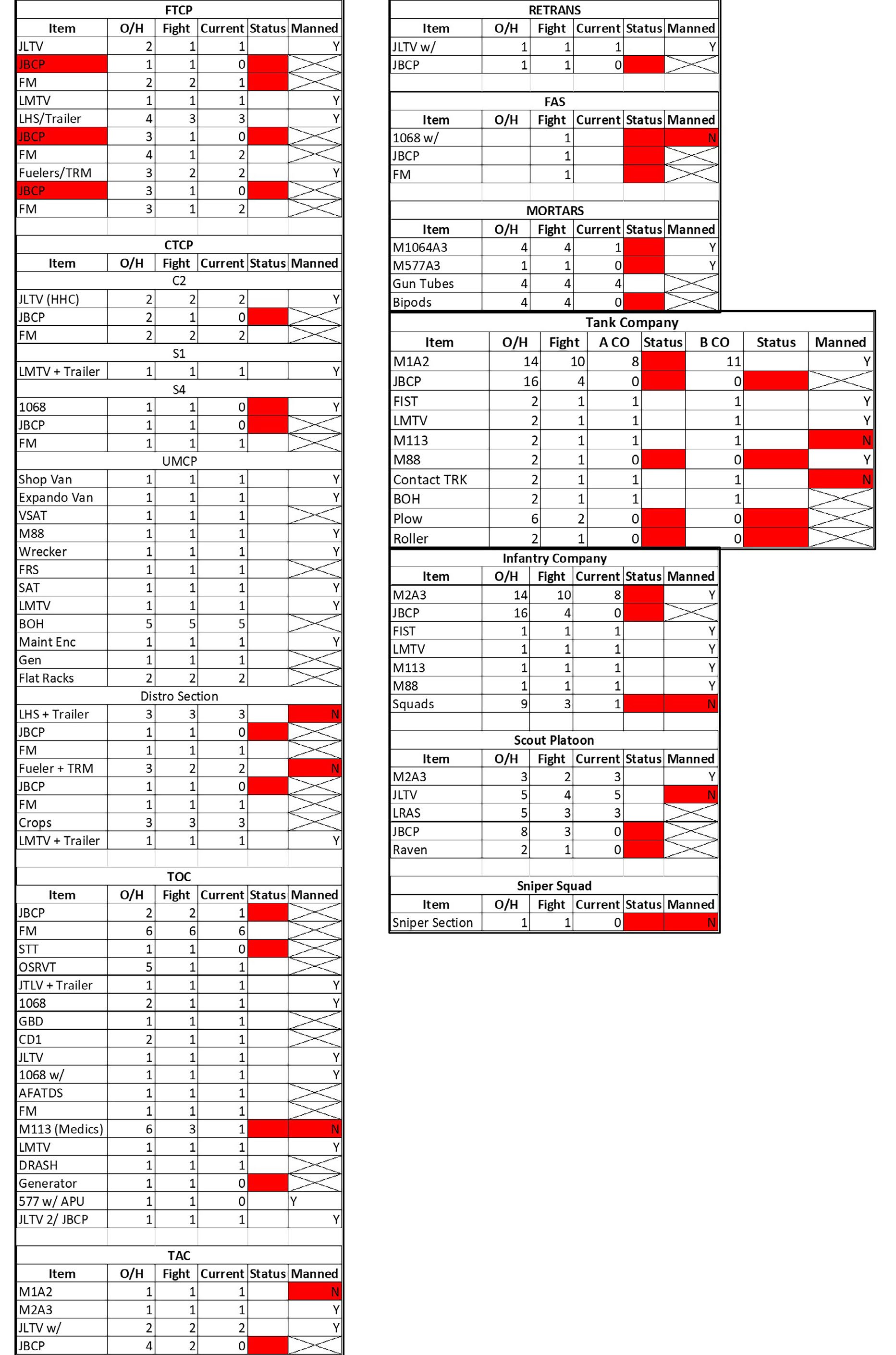

Each formation at echelon has a clear idea of how it fits into the overall fight and the equipment/ platforms

required to deliver their capabilities. The next logical step is to take the fight equipment/ platform

requirements and com-pare them to the current mission capable status of those items.

Table 1. List of capability requirements. (U.S. Army)

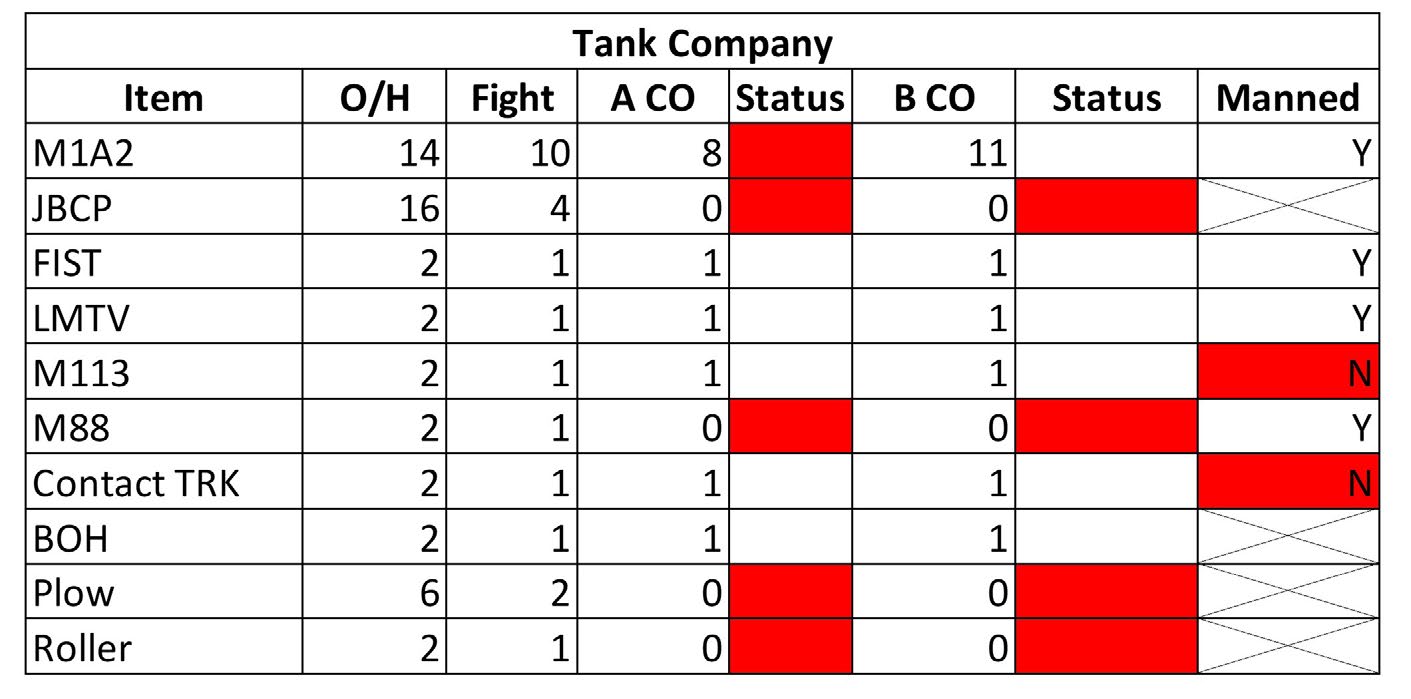

The O/H column is based off the modified table of organization and equipment list, the Fight column is the

requirement defined by the battalion commander, and the company column is the current slant of the item. If the

company fully mission capable (FMC) equals or is greater than the Fight column, the status box remains blank. If

the company FMC is less than the Fight column, the status box turns red. The final column Manned encompasses

personnel readiness. It is a seemingly innocuous column but one that conveys significant information. If the

platform is manned (denoted by Y), it means that the crew is deployable, qualified and meets all rank

requirements (particularly if an NCO vehicle commander is required). If a platform is not manned due to

personnel short-ages, the team can assume risk and not devote maintenance energy to that platform or request

support from higher.

Table 2. Scout capability and equipment/platform requirements. (U.S. Army)

Once done throughout each element and command node, the gaps in readiness (maintenance + personnel) be-come

readily clear. This provides the battalion a clear snapshot of where their maintenance and personnel readiness

gaps exist based on lethality requirements. Leadership can then develop a maintenance strategy over time,

applying the maintenance enterprise against a prioritized list. The battalion maintenance officer then

coordinates with the S-3 Operations Shop and puts the maintenance strategy (unscheduled maintenance, services

and leadership professional development) on the training calendar. This is a way to synchronize training and

maintenance lines of effort based on required lethality capabilities. It is a holistic strategy to streamline

efforts, provide clear guidance and prioritization, and identify areas where the battalion can assume risk. The

overall assessment maintenance and personnel readiness status is captured in Table 5.

Provide clear snapshot

Based on this assessment, the battalion can clearly identify priorities and friction points, and the commander

can provide Training Week (TW)+8 guidance. Furthermore, this dashboard (comprised of Figure 2 and Table 5)

provides a tangible output (status up date) for CAB meetings. The battalion training meeting must entail the

development of capabilities required by the CAB to accomplish its mission while maintenance and personnel

readiness (non-deployable scrubs, etc.) meetings must feed Table 5. Commanders are responsible, with input from

their first sergeants and executive officers (XOs), to update the battalion commander on the dashboard. While

this is a way to organize and assess capabilities and personnel, there are several doctrine, organization,

training, materiel, leadership and education, personnel, and facilities (DOTMLPF) efforts that can better equip

the CAB in building readiness.

Table 3. Consolidated list of capability and equipment/platform requirements. (U.S.

Army)

Even with clear guidance and a detailed maintenance strategy, CABs will continually face challenges in

execution. Below are several DOTMLPF recommendations that would support and streamline maintenance operations.

Table 4. Tank company maintenance and personnel readiness status. (U.S.

Army)

Recommendations to support CAB maintenance

Recommendation #1 (Organization/ Personnel): Radio Equipment Repairers (MOS 94E) and

Computer/Detection Systems Repairers (MOS 94F) Organic to the CAB.

Due to the sheer amount and complexity of communication systems and equipment, it would benefit the CAB to have

one NCO and two 10-level Soldiers organic to the CAB for internal communication and electronics (C&E) and

electronic maintenance (ELM) repairs. Currently, all night vision devices and communication devices are

evacuated to the brigade support battalion for repair/service.

Centralized repair naturally creates a backlog, which prioritizes units executing training for repairs. This

inhibits units preparing for training to conduct proper repairs and services prior to execution. Having organic

C&E and ELM capabilities will decrease overall turnaround time, create shop stock for common repairs, and

provide flexibility in garrison/field environments to build equipment readiness.

Recommendation #2 (Education): Training Deficiencies for MOS 91F (M242 25mm) and MOS 91A (M1

Abrams Schematics).

Small Arms Repairers (MOS 91F) and Tank Mechanics (MOS 91A) do not receive sufficient

training through Army schools to prepare them for operations. The 91F is responsible for servicing the M242 25mm

Bushmaster. They do not receive adequate training during advanced individual training (AIT) to properly service

and repair the weapon system. While master gunners are present to assist in repairs and services, they are only

capable of executing 10/20 level tasks and repairs. The 91F is responsible for 30 level tasks, but they are not

provided the education needed to complete these repairs. The Army must increase training time during AIT for 91F

Soldiers, so they are equipped to execute repairs once they get to their unit. An alternate solution is to make

the repair/services of the M242 a critical task for Bradley mechanics (MOS 91M).

Figure 2. Thunder Battalion coordinates and synchronizes warfighting functions to

mass two companies at the decisive point. (U.S. Army)

91A Soldiers must receive tank schematic training during AIT. This is increasingly significant as the CAB fights

through personnel challenges and many mechanics fulfill positions of greater responsibility than their rank. In

a CAB, junior 91As frequently are faced with tank schematic faults. There is a knowledge deficiency in tank

schematics for junior 91A Soldiers. These tank mechanics do not receive training on tank schematics until the

Advanced Leader Course. Tank mechanics, like their Bradley mechanic counterparts, should receive training on

schematics during AIT.

Table 5. Consolidated list of maintenance and personnel readiness status by element

and command node. (U.S. Army)

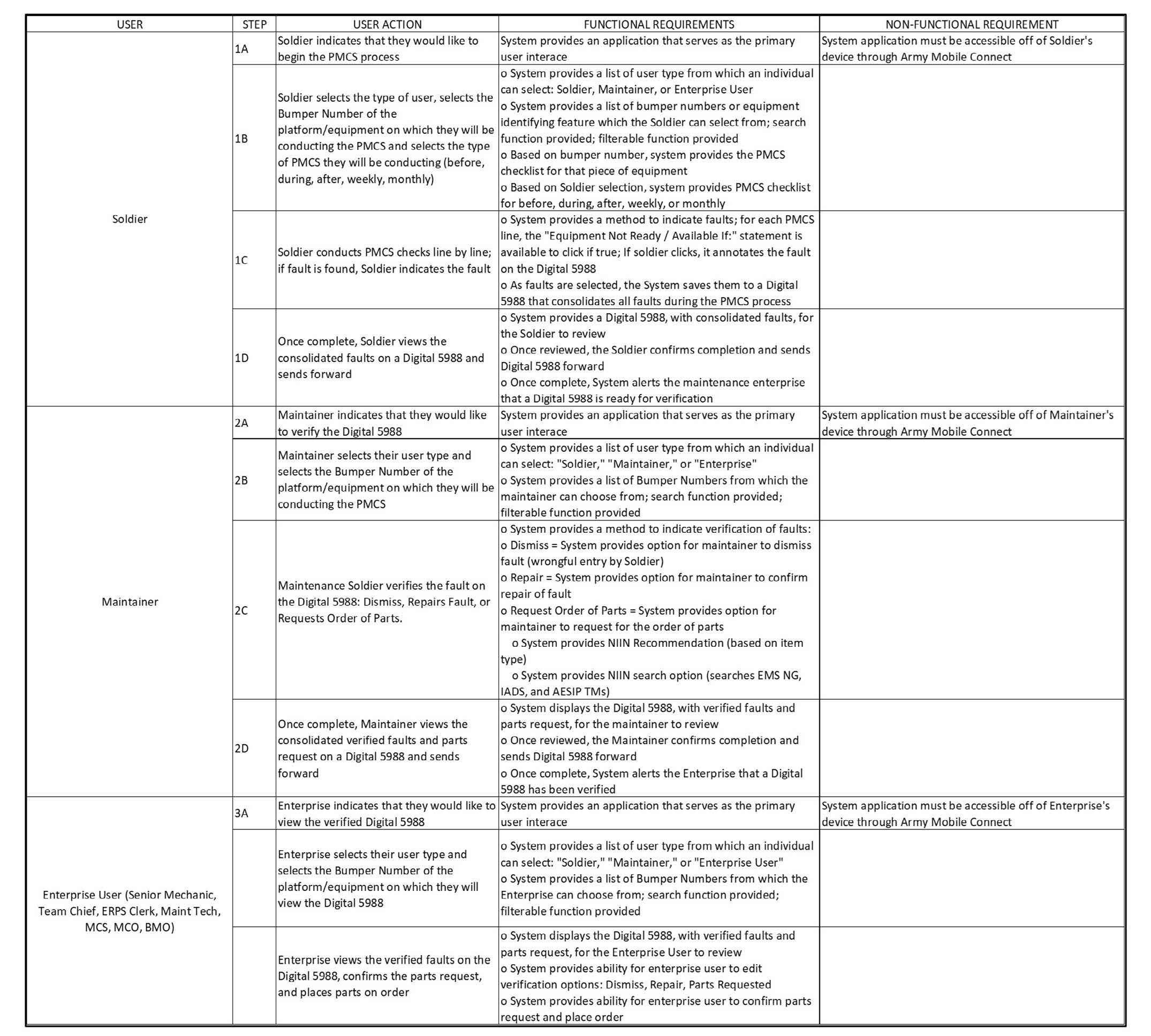

The Maintenance Process and Friction Table 6. Use Case and Functional Requirements for Digital 5988 Software.

(U.S. Army) Points. Soldiers conduct preventative maintenance checks and services (PMCS) and manually annotate

faults on a Form 5988. Mechanics, with a senior mechanic and team chief, then verify the faults and either

dismiss (wrong annotation), repair, or request parts to be ordered. Once this process is complete, the equipment

records parts specialist (ERPS) clerk manually inputs this information into Global Combat Support System – Army

(GCSS-Army). There are two points of friction in this process. The first is the transition from a manual process

(Form 5988) to a digital process (manual input of the 5988 information by the ERPS clerk into GCSS-Army) and the

second is the manual search of parts by National Item Identification Number (NIIN). To alleviate these frictions

points, the following recommendations are presented.

Recommendation #3 (Material): Digital 5988: The amount of error that exists in the current

manual process can be reduced through a digitized system. Additionally, the workload for clerks to manually

input 5988 information into GCSS-Army can also be reduced. A software application with a simple user interface

that can be accessed by all users is advantageous. Table 6 below annotates the use case and functional

requirement for this software application.

Table 6. Use Case and Functional Requirements for Digital 5988 Software. (U.S.

Army)

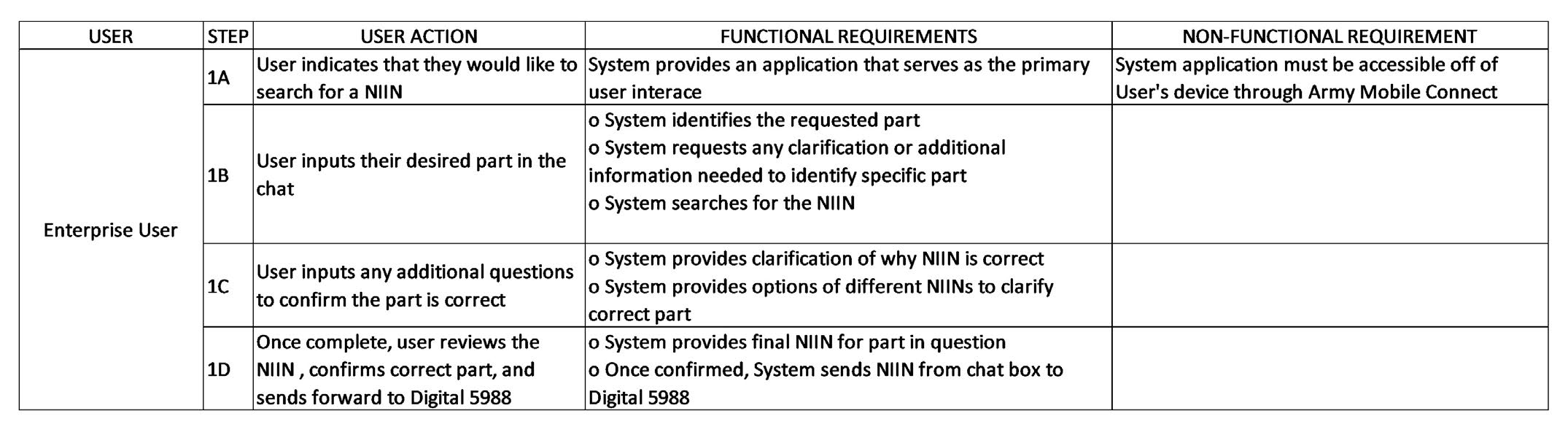

Recommendation #4 (Material): Artificial Intelligence Chatbot for NIIN Search

The current

process to find correct NIINs for parts is inefficient and desynchronized. Currently, users have three disparate

and delinked locations to look for NIINs: Electronic Management System-Next Generation; technical manuals

through the Army Enterprise System Integration Program; and Interactive Authoring and Display Software.

Additionally, there are numerous NIINs for similar parts or like items which induces error.

It is not uncommon for a unit to receive a part only to find that it is the wrong item. An artificial

intelligence (AI) Chatbot that an enterprise user can interact with to search through all three systems

simultaneously would save inordinate amounts of time and reduce human error. The advent of AI software that can

assist in the creation of datasets, train AI, and automate workflows, makes this a reasonable endeavor.

Companies like Palm AI through their Endobyte Software as a Service allows users to customize datasets, execute

AI training and implement AI Chatbots. Below is the use case and functional requirements for this software.

Conclusion

Combined arms battalions are faced with challenges as the Army modernizes and transforms during an inter-war

period. In a time and resource constrained environment, it is imperative Table 7. Use Case and Functional

Requirements for AI Chatbot NIIN Search Software. (U.S. Army) that the CAB commander provides a clear and

detailed fighting strategy to coordinate and synchronize training and maintenance lines of efforts. By defining

lethality at echelon, a CAB can prioritize maintenance requirements and develop a coherent strategy over time

and space. The operational tempo for armored brigade combat teams has been significant and does not look to slow

down. It is important that CAB leadership find efficiencies in the ReARMM framework to increase warfighting

capabilities throughout the formation.

Table 7. Use Case and Functional Requirements for AI Chatbot NIIN Search Software.

(U.S. Army)

Authors

LTC Mike Kim is the battalion commander, 2nd Battalion, 70thArmor Regiment, 2nd Armored Brigade Combat

Team (ABCT), 1st Infantry Division, Fort

Riley, KS. His previous assignments include Command and General Staff College (CGSC) Fellow, Office of Management and Budget, White House, Washington D.C.; Director, Joint Pacific Multinational Readiness Center, Fort

Shafter, HI; Brigade S-3, 196th Infantry

Brigade, U.S. Army Pacific (USARPAC),

Fort Shafter, HI; squadron executive officer, and 8th Squadron, 1st Cavalry Regiment, 2ndStryker Brigade Combat

Team, 2nd Infantry Division, Joint Base

Lewis-McChord (JBLM), WA. LTC Kim’s

military schools include Officer Basic

Course, Fort Knox, KY; Maneuver Captain’s Career Course (MCCC), Fort Knox;

and CGSC, Fort Leavenworth, KS. He

has a bachelor’s of science degree in

comparative politics from the U.S. Military Academy at West Point, NY; a

master’s of science degree military art

and science from CGSC; and a master’s

of engineering degree in systems engineering from Cornell University.

MAJ Nate Bennett is the Secretary of the General Staff, 1st Infantry Division,

Fort Riley, KS. His previous assignments

include battalion XO, 2-70 Armor, 2nd

ABCT, 1st Infantry Division; battalion

operations officer, 2-70 Armor, 2nd

ABCT; team leader in 2nd Battalion, 3rd

Security Force Assistance Brigade

(SFAB); commander, Headquarters and

Headquarters Company (HHC), 2nd Battalion, 87th Infantry Regiment, 2nd Brigade Combat Team (BCT), 10th Mountain Division; and commander, Company B, 2-87 Infantry, 2nd BCT, 10th MTN

DIV. MAJ Bennett’s military schools include Ranger Course; Pathfinder

School; Air Assault School; Airborne

Course; Survival, Evasion, Resistance,

and Escape Level C (SERE-C), U.S. Army

SERE School; and the Infantry Mortar

Leader Course. He has a bachelor’s of

science degree in defense and strategic

studies from the U.S. Military Academy,

West Point, NY; and a master’s degree

in operational studies from the U.S.

Army Command and General Staff College.

CW3 Jason T. Amsdell is the battalion

maintenance technician, 2nd Battalion,

70th Armor Regiment, Fort Riley, KS. His

previous assignments include battalion

maintenance technician, 2nd Infantry

Brigade Combat Team, 11th Airborne

Division, Joint Base Elmendorf-Richardson, AK; battalion maintenance technician 1st Battalion, 325th Airborne Infantry Regiment, 82nd Airborne Division, Fort Liberty, NC; and maintenance

management NCO, 7th Special Forces

Group Airborne, Eglin Air Force Base

(AFB), FL. CW3 Amsdell’s military

schools include Jumpmaster Course,

Eglin AFB; Unit Movement Officer

Course, Fort Richardson, AK; Standard

Army Maintenance System–Enhanced (SAMS-1E) Course, Fort Richardson;

Standard Army Retail Supply System -

Level 1 (SAARS1) Course, Bagram, Afghanistan; Advanced Leaders Course;

Senior Leaders Course; Warrant Officer

Basic Course; and Warrant Officer Advanced Course, Fort Gregg-Adams, VA.

CW3 Amsdell completed Lean Six Sigma - Army Business Management. His

awards include the Bronze Star Medal,

Meritorious Service Medal and the

Combat Action Badge.

1LT Collette Benavidez is the battalion

maintenance officer, 2-70 Armor Regiment, 2nd ABCT, 1st Infantry Division,

Fort Riley, KS. Her previous assignments include maintenance control officer, H Forward-Support Company

(FSC), 2-70 Armor, 2nd ABCT; maintenance platoon leader, D FSC, 5th Squadron, 4th Cavalry Regiment, 2nd ABCT, 1st

Infantry Division; maintenance control

officer, D FSC, 5-4 Cavalry, 2nd ABCT;

and S-3 Overstrength, HHC, 299th Brigade Support Battalion, 2nd ABCT. 1LT

Benavidez completed the Quartermaster Basic Officer Leader Course, Fort

Gregg-Adams, VA. She has a bachelor’s

of arts degree in international relations

from American University.

Acronym Quick-Scan

ABCT – armored brigade combat team

AESIP – Army Enterprise Systems

Joint Battle Command-Platform

AFATDS – Advanced Field Artillery

Tactical Data System

AFB – air force base

AI – artificial intelligence

AIT – advanced individual training

BAS – battalion aid station

BCT – brigade combat team

BMO – battalion maintenance officer

C&E – communication and electronics

CAB – combined arms battalion

CGSC – Command and General Staff

CTCP – combat-trains command post

DOTMLPF – doctrine, organization, training, materiel, leadership and education, personnel,

and facilities DRASH – Deployable Rapid Assembly Shelter

ELM – electronic maintenance

EMS – Electronic Management System

ERPS – equipment records parts specialist

EVAC – evacuate

FiST – fire-support team

FMC – fully mission capable

FPOL – forward passage of lines

FSC – forward-support company

GCSS-Army – Global Combat Support

HHC – headquarters and headquarters company JBC-P –

JLTV – Joint Light Tactical Vehicle

LMTV – Light Medium Tactical Vehicle

LOGPAC – logistics package

LRAS – Long-Range Acquisition System

MCO – maintenance control officer

MCS – mission-command system

MOS – military occupational specialty

NAI – named area of interest

NG – National Guard

NIIN – National Item Identification Number

OSRVT – One System Remote Video Terminal College

PMCS – preventive-maintenance checks and services

PIR – priority intelligence requirement

ReARMM – Regionally Aligned Readiness and Modernization Model

RPOL – rearward passage of lines

RETRANS – retransmission

STT – Satellite Transportable Terminal

TAC – tactical command post

TOC – tactical operations center

TM – technical manual

UMCP – unit maintenance collection point