BCT Armor Reserve:

An Approach to Large-Scale Combat Operations

By CPT Leo E. Li

Article published on: October 1, 2024 in the Armor Fall 2024 Edition

Read Time: < 24 mins

Figure 5: Elements from 2nd PLT, Company C, 1-8 Infantry and fire support assets prepare to

displace to their next staging area. (U.S. Army photo by SGT James Drettwan, Company C, 1st Battalion, 8th

Infantry Regiment)

As the U.S. Army continues its transition back to large-scale combat operations, it must also place emphasis on

reserve operations, which will be critical in high-intensity, high-casualty fights against near peer military

threats. In 2023, 3rd Armored Brigade Combat Team (ABCT), 4th Infantry Division (“Iron Brigade”) participated in

National Training Center (NTC) Decisive Action Rotation 24-02, in which Crazy Horse Company of 1st Battalion,

8th Infantry Regiment (“Fighting Eagles”) served as the BCT’s armor reserve during force-on-force (FoF)

operations.

The purpose of this article is to capture tactics, techniques, and procedures (TTPs) used and considered by Crazy

Horse Company to supplement existing literature on reserve unit operations. The intent is to offer armor

companies serving as a BCT’s reserve component a doctrinal starting point, from which units can develop or

revise their own standing operating procedures (SOPs) to match the mission sets the role requires.

As recent conflicts such as the Russo-Ukrainian War have shown, attrition remains widespread; initial attacks or

operations by even well-armed, well trained units can reach culmination and even defeat without exercising or

maneuvering reserve forces to sustain and support those operations.1 Therefore, how the reserve trains, fights, and wins

decisively on the battlefield must be given appropriate consideration when a BCT plans, resources and executes

its missions. Very little of U.S. Army armor doctrine focuses on the reserve element itself. Additionally,

recent U.S. Army Training and Doctrine Command and Center for Army Lessons Learned (CALL) literature does not

offer specific TTPs or SOPs for how the reserve unit should operate in the wider context of BCT operations. This

article lays out just one possible approach to serving as a BCT’s armor company reserve; the recommendations of

this article are based both on Crazy Horse’s SOPs and on after-action reviews conducted with the NTC Operation

Group’s Tarantula Team observer/coach/trainers

This article will focus more on the micro-elements and minutiae of operating the armor company as a reserve – how

to plan, maneuver, sustain itself, and coordinate with higher or neighboring echelons – rather than on more

macro-elements about how the reserve element should be employed. Furthermore, while Crazy Horse Company served

as a reserve armor company in its organic ABCT, the hope is that some of the TTPs presented in this article

might also apply and be useful to Stryker brigade combat teams (SBCTs) that receive armor company attachments,

and potentially infantry brigade combat teams (IBCTs) that receive M1 Abrams or M10 Booker companies in support

of their combat operations.

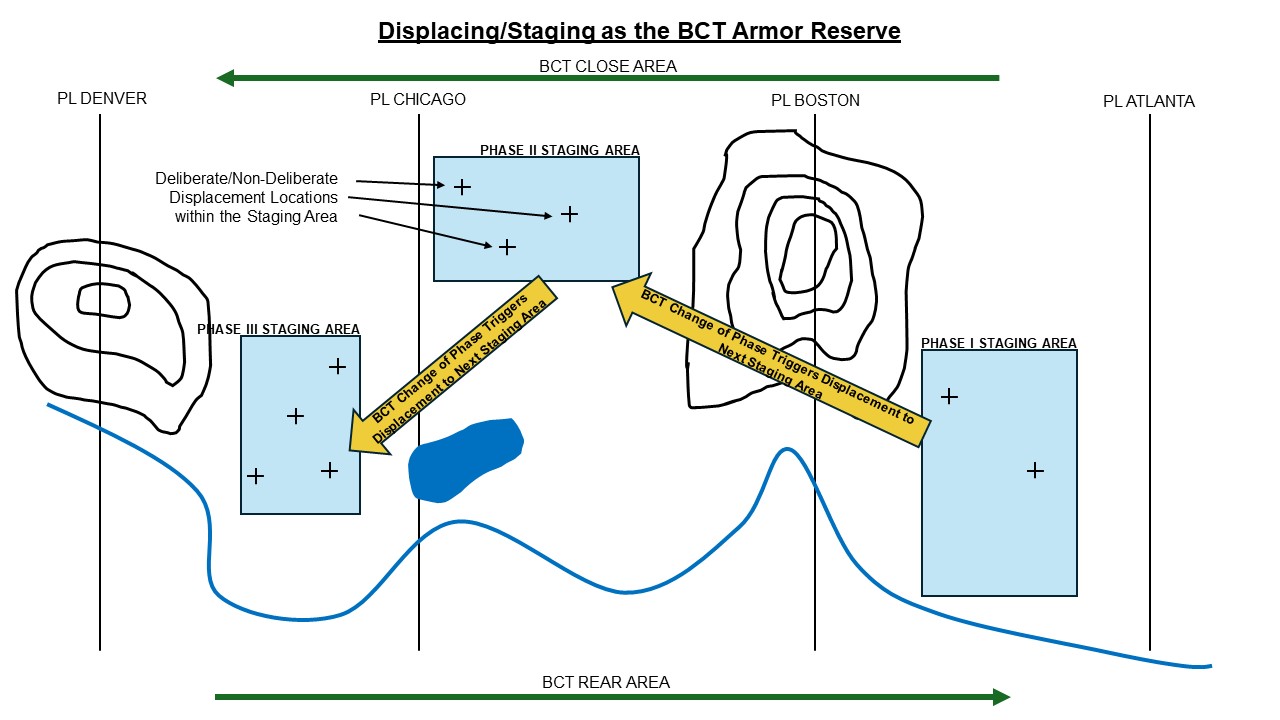

Figure 1: Like the conduct of Position Areas of Artillery (PAAs), an armor BCT reserve can

have pre-planned areas where sister and higher echelons know where they will stage and operate during a

specific phase of the BCT operation. If the unit takes contact, it can displace to any location within the

pseudo-PAA, increasing survivability, providing deconfliction, and maintaining predictability for higher

echelons. As the BCT transitions between phases, it can move towards/ away from the close area or FLOT into

another staging area to better posture for activation. If communicated beforehand, this also provides higher

echelons additional predictability across phases in case mobilizing the reserve is required. (U.S. Army

graphic)

Command and control

Army Doctrine Publication (ADP) 3-90, Offense and Defense, defines a reserve as “that

portion of a body of troops that is withheld from action at the beginning of an engagement, to be available for

a decisive movement.”2 Field Manual

(FM) 3-96, Brigade Combat Team, assumes that a BCT reserve is usually a company or

battalion-minus sized element, while battalions serve as the key decisive units for the brigade commander.3 During its NTC rotation, Crazy

Horse Company, its fire-support team (FST), and its field maintenance team (FMT) served as that reserve.

Using an organic company as the BCT reserve, rather than a company team or other task organization, allowed the

commander to employ long-developed relationships with subordinate leaders and their knowledge of their own

assets, without the friction of developing new relationships, company-specific SOPs, or other kinds of

coordination that would be necessary if the commander’s subordinate units included those not usually their own.

While Crazy Horse Company received additional attachments during the rotation, such as engineer support during

area defense operations, these were usually short-term relationships meant for specific mission sets

During the entirety of force-on-force operations, Crazy Horse was placed either under operational command (OPCOM)

or operational control (OPCON) of the BCT headquarters. The BCT command team and staff were primarily

responsible for planning, assigning, and coordinating missions, tasks, and operational plans for the company.

The organic battalion, although not possessing operational command or control of the armor company, remained

administratively responsible for it. This responsibility by the battalion included sustainment and logistical

support. The operational status of Crazy Horse flipped between OPCOM and OPCON depending on whether a need

existed to further detach tank platoons from the reserve element and who would make that decision. Usually, this

decision-making took the form of a conversation the battalion and BCT commander and their staffs.

Maintaining administrative, logistical, and sustainment responsibility with the organic battalion proved a

critical decision in the reserve company’s readiness. This allowed the company to leverage existing, organic

relationships within the battalion – relationships that could be leaned on to resolve friction and problems as

they arose. This also allowed the reserve company to take advantage of existing logistical infrastructure

(combat trains command post (CTCP), unit maintenance collection point (UMCP), contingency command post (CCPs),

logistical resupply point (LRPs)) instead of having to build its own or rely on last-minute, provisional command

and control (C2) relationships heavily dependent on time and space for both the reserve element and the

battalion ordered to provide resources. Predictability built into command and support relationships, for both

the reserve unit and higher echelons, ensures smoother operations and reduces risk of either echelon being

unprepared as operations continue to face stressful operations tempo (OPTEMPO) and increasing friction.

For SBCT and IBCTs, this course of action is not immediately translatable. Any attached armor company may not

have any organic or long-term relationship with a battalion it can leverage. Therefore, the armor company’s

administrative and logistical responsibilities should be placed with a battalion with strong and adaptive

sustainment capabilities. Stryker and light infantry leaders may not always comprehend or be able to manage the

significant differences in logistical support an armor company needs, particularly when it comes to frequency or

scope of its Class III (petroleum, oil, and lubricants) and Class V (ammunition) requirements.4 The armor company should therefore

be placed with a battalion that has an extremely capable forward support company (FSC) that can sustain both its

organic fleet and a company of M1 Abrams.

Alternatively, a brigade support battalion (BSB) may have the assets and supplies to directly support an armor

company. However, that BSB must then be able to conduct resupply and other sustainment operations closer to the

forward line of own troops, where the company may find itself engaged. Ultimately, a predictable and

well-established command and administrative structure with a singular battalion and brigade headquarters,

instead of a relationship that requires potential coordination with several battalions and companies across time

and space, ensured the stability required for effective planning and operations for the reserve armor company.

Communications

Based on the command and support relationships described above, Crazy Horse Company used the following

communication SOP when dealing with higher echelons:

- BCT Command and Operations/ Intelligence (O/I): The company commander was primarily

responsible for monitoring these FM nets and Joint Battle Command-Platform (JBC-P) chat rooms, allowing the

reserve element to receive intelligence and operational updates for the entirety of the rotation. When

expecting activation by the BCT commander, the company commander focused on the BCT command channels.

Otherwise, the BCT S-3 or S-2 would provide updates to the reserve company commander.

- Battalion Command and O/I: the Crazy Horse command team monitored these nets for general

situational awareness but used these primarily to coordinate logistical and sustainment operations. The

company executive officer (XO) and first sergeant (1SG) were responsible for submitting logistics statistics

(LOGSTATs) at least twice daily to the appropriate battalion-level stakeholders. As necessary, the company

XO also participated in any maintenance or logistical syncs with the FSC, maintenance control section (MCS),

and the battalion staff.

- Company command post (CP): the company CP monitored both the battalion and brigade net,

focusing on the channel related to the most critical operation at a given time.

The company also attempted to keep at least two working radios in each tank. Currently, an armor company modified

table of organization and equipment (MTOE) includes six radios per platoon. One issue that arose was following

attrition by the enemy. Wing tanks struggled to simultaneously monitor a higher echelon net; without one radio

required hopping off its platoon net. Even if the section was simply degraded or separated from the platoon or

company, having multiple systems in every tank would have alleviated coordination issues that arose as the

company spread out and was eventually degraded across space and sometimes multiple terrain features. A potential

quick fix to this issue is to borrow additional radios from a battalion or BCT S-6 section if the unit is unable

to increase its organic amount on hand.

Additionally, communications security (COMSEC) remains critical. To ensure minimum friction COMSEC and equipment,

M1 loaders were sent to a COMSEC custodian course prior to the rotation and trained on loading, filling and

dropping COMSEC. This allowed most platoons to self-diagnose and troubleshoot a majority of COMSEC issues and

maintain a Simple Key Loader (SKL) at the platoon level. This alleviated much of the demand for the company

communications representative and outside assistance from a battalion or BCT S-6 section, allowing the reserve

armor force to operate as independently as possible on this front without major restraints and requirements from

higher echelons

Maintenance continues to be vital to effective communications. Home station units should constantly be using

their BCT’s communications & electronics (C&E) shops to fix their FM radios and JBC-P equipment. Waiting until

the last-minute to use C&E following 10-level operator preventive maintenance checks and services (PMCS) and

troubleshooting is a recipe for failure. C&E shops will cease operations early to pack for deployment and then

take time to establish themselves forward. Problems are therefore best identified and resolved earlier rather

than later.

Planning Priorities

Because of its OPCOM/OPCON relationship with the BCT headquarters, the armor reserve force should receive its

planning guidance from the brigade level. Reliance on the battalion to provide BCT-level graphics and overlays,

commander’s intent, and potential objectives can both divert the battalion staff’s attention away from their own

objectives and planning priorities, while potentially limiting the reserve commander’s situational awareness and

understanding by receiving information only pertinent to the battalion’s piece of the area of operation (AO).

During NTC Rotation 24-02, Crazy Horse attended BCT OPORD briefs and rehearsals. The company commander and 1SG

could learn the entire BCT’s AO and operational intent, since the reserve force could be activated to support

any number of possible contingencies. Consequently, this made attendance at battalion-level rehearsals

repetitive from an operational standpoint. However, attendance at battalion-level OPORDs was still useful to

monitor and advise on sustainment operations, since the company was still reliant on the battalion for

sustainment and maintenance operations. Therefore, whenever possible, the company commander focused on BCT OPORD

briefs and rehearsals, often attending alongside battalion commanders, while the XO and 1SG attended battalion

briefs and rehearsals, when possible, to maintain an updated logistical picture for the company.

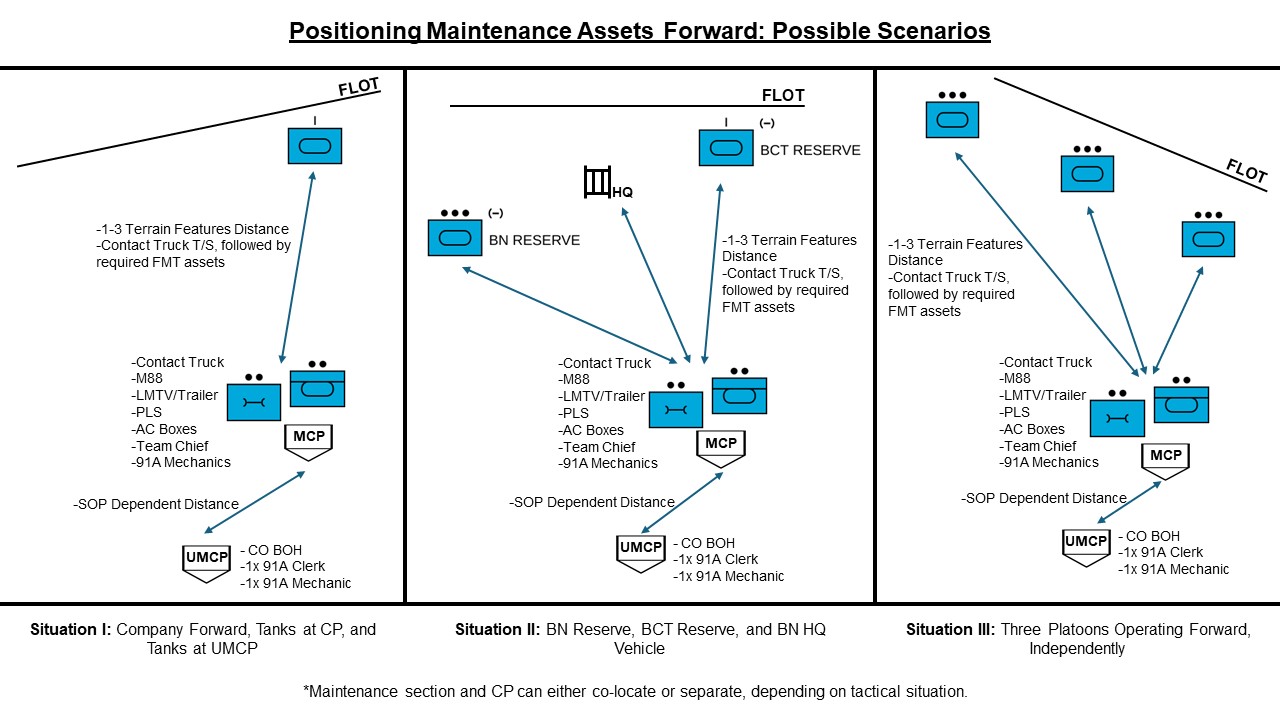

Figure 2: The field maintenance section (FMT) should be able to support up to three distinct

units or nodes forward, while maintaining lines of communication or support with the UMCP. The FMT should

therefore be positioned to minimize likelihood of contact, receive adequate protection, and still be

postured to support forward assets or recover assets back to the MCP or UMCP. (U.S. Army graphic)

Due to the number of contingencies for which a reserve company could be activated to support its BCT’s

operations, company and platoon-level troop leading procedures and planning adapted accordingly. At the company

level, OPORDs focused heavily on paragraphs one and two over paragraph three’s scheme of maneuver. Because the

company could be activated to support any battalion objective, or even a new objective created by circumstance,

situational awareness of the entirety of the AO and its operations was more critical than any specific plan of

action by the company itself. While the company commander could predict where activation was most likely due to

the levels of risk and priorities at the BCT level, focusing on a singular objective would make it ill-prepared

to conduct an alternative operation.

To adapt, all tank commanders and above attended the company OPORD, allowing more time for platoons to

concentrate on back-briefs and rehearsals. Compacting parts of the company’s troop-leading procedures freed more

time for company and platoon rehearsals of multiple contingencies over one specific course of action. Tactically

agile and adaptive platoon leaders and sergeants are essential – those who understand company SOPs and battle

drills deftly enough to be able to apply them to constantly changing circumstances.

Fires and Survivability

The FST attached to the reserve force should establish, prior to combat operations, a special priority of fires

due to the nature of the operations it is attempting to support. The reserve’s FST can and should not be treated

as another line company’s fires targets. If activated, the BCT commander is deliberately devoting additional

firepower to a specific operation, either to avoid failure or to exploit a decisive point on the battlefield.

When activated, the reserve company’s FST should “jump” the priority of fires for a short period of time,

superseding perhaps all but the company or battalion conducting the decisive operation of the BCT. For Crazy

Horse Company, not having this priority of fires, even when deployed to prevent enemy armored envelopments or

supplementing an area defense at risk of enemy breakthrough, allowed numerous targets of opportunity, including

enemy breaching elements to move and maneuver freely when operating just outside the M1’s main gun range.

Conversely, the reserve force must react quickly and decisively to enemy indirect fires, whether that involves

artillery or drones and loitering munitions. While opposing forces will use these assets to target command

posts, logistical nodes, and other high-signature and key targets, armor companies were also subject to attacks,

especially when supporting operations at decisive points on the battlefield. While not in combat, armor reserves

would do well to have pre-planned displacement locations, like how artillery units use Position Areas for

Artillery. This would reduce lastminute identification of new displacement locations, while still providing both

the unit and higher echelons some predictability of where the reserve is staged at a given point in an

operation.

Armor companies will also do well to conduct anti-unmanned aerial vehicle (UAV) training at home station and

attempt to acquire drone buster assets whenever possible, especially when conducting operations like a defense

where contact with UAVs could force the unit to displace from tactically advantageous or key positions.

Camouflage of vehicles and CPs can also minimize risk of detection or reduce the information obtained by the

enemy. For instance, camo netting covering a tank’s identifiers can prevent enemy forces from determining

whether it belongs to the commander or another key leader.

Figure 3: M1A2 crew from 3rd PLT, Company C, 1-8 Infantry moves to a secondary CP location

during force-on-force operations as part of NTC Decisive Action Rotation 24-02. (U.S. Army photo by

Operations Group/Fort Irwin Public Affairs Office)

Sustainment

While an armor company is OPCOM/ OPCON to an ABCT headquarters, the reserve armor company should rely on its

organic battalion for sustainment and support. This leverages long-term relationships; the battalion’s FSC is

likely practiced in accounting for its logistical requirements. For armor companies augmenting SBCTs and IBCTs,

it is critical that the company is supported by a strong battalion staff and agile FSC that understands and can

support the relatively immense sustainment requirements that a company of M1A2s requires to remain in the fight.

Crazy Horse therefore relied on the Fighting Eagles for its sustainment infrastructure. LRPs, for instance, were

either co-located with the CTCP or placed at a pre-determined location communicated to the 1SG for conducting

resupply operations. LOGSTAT requirements were sent twice a day by the XO to the battalion S-4, FSC command

team, battalion maintenance officer, and battalion XO.

The exact times of these LOGSTATs and LRPs depended on battalion and the FSC: their ability to process requests

and move assets to and back from the LRPs on time to support the next resupply.

The most critical sustainment to consider for the armor reserve force was Class III. An idle M1A2SEPv2 Abrams

tank consumes 3,600 gallons of fuel per day.5 To maintain a steady OPTEMPO and readiness status as the reserve, the unit

required refuel multiple times in a 24-hour period. Whether or not multiple LRPs are conducted for Class III(B)

or whether fuelers remain attached is a tactical decision; both options sustain the company, but one leaves a

fueler asset forward longer and increases risk of becoming a target for the opposing force, but with the benefit

of being able to conduct refuel at any time.

As part of the battalion SOP, an emergency fueler was held at the CTCP. The purpose of this fueler was for the

battalion commander to authorize and conduct an emergency resupply at any time for any line company to exploit

new developments or conduct extended operations that required another 12 hours of combat effectiveness. Twice

during force-on-for operations, the emergency fueler was released to the reserve force so it could mobilize and

operate quickly against targets of opportunity that were at least 12 kilometers forward without waiting for the

twice-daily resupply prior to movement.

Class III(P) should also be precisely monitored by platoons and the XO, so that needs are anticipated long-term

in LOGSTATs to higher echelons. SOPs should require that M1 crews enter combat operations with at least three

days of supply (3DOS) of Class III. LOGSTATs should anticipate requirements out to 72 hours of operations.6

Loads and resupplies should interpret “3DOS” based on the unique requirements of the tanks. For instance, one of

Crazy Horse’s tracks had a long-term issue which consumed turbo-shaft at higher-than-normal rates. As a result,

that tank and the platoon carried more turboshaft compared to the rest of the company to meet the 3DOS standard.

Crazy Horse found that 3DOS allowed the vehicles to conduct operations and maintenance for consistently more

than three days. For instance, not all vehicles required grease at the same rates, based on each tank’s specific

track tension and health. Infrequent but more complex maintenance, like draining engines, could generally be

accomplished with the petroleum, oil and lubricants (POL) on hand, although the unit found early on that risk to

mission caused by limited Class III could be further mitigated if the FMT carried its own reserve supply of POL,

with exact quantities of specific Class III(B) based on long-term trends and needs of the fleet.

Maintenance, ESR, and parts flow

A robust maintenance program and system is the key to success for an armor company to conduct and maintain combat

operations over the long-term. Failure to anticipate, prevent, and resolve maintenance issues efficiently

increases reliance on other echelons and outside systems, reducing a reserve force’s readiness and ability to

operate independently.

All maintenance assets are mission essential. Therefore, FMTs should attempt to man and bring all its equipment

forward, staging it either at a company maintenance control point (MCP) or at the battalion UMCP. For Crazy

Horse’s FMT assets, all vehicles and trailers, AC boxes, and the Forward Repair System were brought forward in

the company trains, while the company BOH container was left with the UMCP. No maintenance assets were left in

the rear

Successful maintenance begins long before the start of combat operations. First, service schedules for the unit’s

equipment must be prioritized and protected. Well-planned and executed services, prior to training and

operations, are undoubtedly the most important means of maintaining or improving the readiness of the fleet.

Second, strong maintenance and command teams should anticipate demands and build up load plans and bench stocks

months in advance. For instance, Class II supplies such as batteries (AAA, FM radios, etc.) can be ordered and

stockpiled before; attempting to acquire these during operations becomes immensely more difficult. Similarly,

Class IX overaged, repairable-Item lists (ORILs) are stockpiles meant to sustain the company without additional

support from higher echelons for at least 72 hours. This stockpile is critical during the first few days of

combat operations, when the Supply Support Activity (SSA) may still need time to establish and resume

operations. Furthermore, the SSA’s location jumps require a pause in processing Class II/IX requests and

distributing them to lower echelons. Therefore, maintenance teams should work to restock Class IX ORILs prior to

deployment. Additionally, the company should work with its battalion MCS section to adjust the company’s

command-directed lines to add additional, specific Class IX equipment to its ORILs that the maintenance team

predicts may be necessary based on the personality and long-term trends of the fleet.

Once deployed forward, a BCT armor reserve may have to effectively operate independently from higher headquarters

or other maintenance assets. Especially when attached to an SBCT or IBCT, other maintenance expertise on M1s and

their associated equipment outside the company itself may prove extremely limited. Therefore, the armor reserve

force must be able to operate as independently as possible. For Crazy Horse, the command team positioned the FMT

to support as many as three distinct nodes of M1 tanks. Military operational specialty (MOS) 91A tank mechanics

assigned to the battalion service & recovery (S&R) section of the FSC remained at the UMCP to augment battalion

maintenance and recovery efforts, while always keeping a minimum tank mechanic presence at the UMCP. Vehicles

that could be fixed on the spot had parts and mechanics brought forward. Otherwise, the tank would be recovered

to the MCP or UMCP for additional troubleshooting. The MCP was either collocated with the company train or left

with an FMC tank to provide protection. When displacing, the CP and MCP can separate to maintain as low of an

electronic signature as possible

When conducting maintenance operations, an up-to-date and accurate equipment-status report (ESR) remains critical

to the unit’s ability to maintain or return to the fight. If a maintenance issue requires an 02 code priority

designator deadline on the ESR, the unit should do so as soon as possible, having the XO communicate immediately

to the battalion MCS. It’s important to ensure the FMT is equipped with all necessary equipment to conduct major

maintenance operations, including protective coverings and tarps to conduct engine pulls in the field if

necessary. The XO should also enter the field with three to five spare sets of 2404s or 5988s. While these

documents may be blank or old, having them on hand allows crews and mechanics to conduct PMCS and compile faults

easily. If conducting PMCS and fault verification every 72 hours, three to five sets of 2404s allow for 9 to 15

days of coverage, allowing the company to conduct documentation of its PMCS for nearly two weeks if printer,

UMCP, or SSA capabilities are limited or degraded during operations.

FMT should verify faults and submit the form 5988s to the UMCP at the end of the 72 hours. Critical parts

required for continued operations should be added to LOGSTATs and sent to the UMCP immediately after

verification. This double tapping generally ensured battalion MCS was tracking parts requirements, so long as

the MCS ensured these requests were not duplicated because they came from separate channels. XOs and platoon

leaders would also do well to bring quick-reference guides that list National Stock Numbers (NSNs) for high-risk

and high-demand parts. For parts like these, being able to immediately identify the NSN without needing to

conduct research by clerks further truncated the time required to process these parts.

Maintain relationships

Even when trying to operate independently, maintaining relationships across the BCT are critical, especially when

operating in an ABCT. Team chiefs and XOs can work with counterparts in other companies to obtain parts and

increase the BCT’s overall readiness if the opportunity exists. Coordinated efforts at the lowest level are

low-risk opportunities that can increase the health of fleets, especially if the SSA is indisposed or requires

long lead-times for specific Class IX parts that are on hand elsewhere.

Finally, a strong culture of operator ownership of their vehicles is critical to a unit’s maintenance success and

can be a force multiplier when attempting to operate independently for as long as possible. Issues like track

tension and POL issues can be identified and fixed during PMCS and following every major movement. Swapping

roadwheels, checking fluids, can all be conducted at the crew level often and should be done in anticipation of

faults, not after. Command teams should enable this by encouraging ownership but also providing time and space

between operations to conduct these activities effectively.

Conclusion

Crazy Horse Company’s operations as the BCT reserve proved critical at key junctures in the Iron Brigade’s

operations against Blackhorse during FoF operations. While much credit can go to the decision-making processes

by senior leaders on when, where, and how to utilize the company in support of ongoing missions, reserve units

can only accomplish these missions if working SOPs and TTPs are put in place before and during operations that

enable readiness and success. Commanders and their teams ultimately have little say in how they are employed by

higher echelons. Their focus instead should emphasize ensuring a lethal and ready force, prepared to mobilize

and execute for any potential contingency.

A single but fully functional armor company possesses extraordinary capabilities that it can deploy on behalf of

higher echelons. The effects it brings to the battlefield in terms of lethality are still unmatched. Aversion

towards aggressively and proficiently employing such a force in combat risks self-inducing stalemate and even

defeat when courses of action are still potentially available. BCTs would do well to ensure reserve elements,

especially mechanized assets, are effectively implemented in operational planning to ensure success.

CPT Leo E. Li is the aide-de-camp to the Deputy Commanding General Support,

4th Infantry Division, Fort Carson, CO. His previous assignments include executive officer, Headquarters

and Headquarters Company (HHC), 1st Battalion, 8th Infantry Regiment (1-8 Infantry), 3rd ABCT, 4th

Infantry Division; executive officer, Company C, 1-8 Infantry, 3rd ABCT; tank platoon leader, Company C,

1-8 Infantry, 3rd ABCT; liaison to the 21st Panzer Brigade, HHC, 1-8 Infantry, 3rd ABCT; and assistant

S-3, HHC, 1-8 Infantry, 3rd ABCT. CPT Li’s military schools include Tank Commanders Course, Bradley

Commanders Course, Dismounted Counter-Improvised Explosive Device Course, Scout Leaders Course, and

Armor Basic Officer Leaders Course. He has a bachelor’s of arts degree from Princeton University with a

major in history and a minor in international relations. CPT Li participated in One Rotation: Operation

European Assure, Deter, and Reinforce (March – December 2022).

Notes

1. Valerii Zaluzhnyi, Modern Positional Warfare

and How to Win It (2023).

2. Department of the Army, ADP 3-90, Offense and

Defense, (Washington, D.C.); 2019, 2-15,

https://armypubs.army.mil/epubs/DR_pubs/DR_a/ARN34828-ADP_3-90-000-WEB-1.pdf.

3. Department of the Army, FM 3-96, Brigade

Combat Team (Washington, D.C.), 2021, 4-21,

https://armypubs.army.mil/epubs/DR_pubs/DR_a/ARN31505-FM_3-96-000-WEB-1.pdf.

4. Department of the Army, “Tank Companies: Considerations

and References for Task Organization, 22-735,” Center for Army Lessons Learned (CALL),

(Fort Leavenworth, KS); 2022.

5. CALL, 2