Modification of the Joint Lightweight Tactical Vehicle into a functional Fire Direction Center

By MAJ John Meier, LTC Adam Ropelewski & SFC Michael Limpert

Article published on: March 25, 2025 in Field Artillery 2025 E-edition

Read Time: < 9 mins

Most of us have been in, or are currently in, units undergoing modernization. Though often tedious, time intensive and organizationally consuming, modernization is a critical component of the Army’s ability to meet its mission both now and in the future. As we look to Large-Scale Combat Operations (LSCO) as the pacing threat, the modernization of legacy equipment and systems is likely to continue. So, what happens when this creates unintended or unforeseen gaps? I offer to you a recent example of such a scenario experienced by 2nd Battalion, 77th Field Artillery Regiment (2-77 FA) during its own conversion as a part of the modernization process and is applicable across the Field Artillery community. Ideally, this article demonstrates an achievable method for converting the Joint Lightweight Tactical Vehicle (JLTV) into a fire direction center (FDC). But more importantly, it will highlight how the ingenuity, hard work and perseverance of Soldiers supplements modernization as new capabilities that create unintended gaps emerge.

In 2020, 2-77 FA, as part of 2/4 Infantry Brigade Combat Team’s (IBCT) transition to 2/4 Stryker Brigade Combat Team (SBCT), transitioned from a M119/M777 composite battalion to a M777 pure at Fort Carson, Colorado. This transition included the introduction of the JLTV as the replacement to the aging High Mobility Multi-Purpose Wheeled Vehicle (HMMWV) across the brigade. A byproduct of this not accounted for during testing was the ability to convert the FDC from a HMMWV-based design to the JLTV. The JLTV is superior to the HMMWV in many ways; however, the legacy HMMWV FDC was not transportable to the JLTV, its replacement (2SBCT was not fielded the Stryker FDC variant). With disposition instructions to turn in all HMMWVs, this presented a unique challenge to the formation as it began collective training in preparation for a National Training Center (NTC) rotation.

As we looked to overcome this friction, we turned to the Mine-Resistant Ambush Protected (MRAP) All-Terrain Vehicle (M-ATV) as a substitute. We had challenges in mounting radios in locations for easy access (for troubleshooting), space issues (four- seats are not conducive to a collaborative FDC), noise/light discipline issues (windows in the M-ATV or open doors to facilitate collaboration) and antenna mounting challenges. This worked as a temporary solution but was not effective or efficient in operation, whether moving or stationary. While we began collective training with the M-ATV setup, one battery was tasked with identifying and working towards a JLTV solution.

There were three foundational problems with using the JLTV as an FDC. First, the bed of the two-seater JLTV is not the same as the two-seater HMMWV. The HMMWV’s infrastructure (bench, table, radio mounts, antenna mounts, etc.) that supported the FDC suite of communications (AFATDS, radios, antennas, power supply, etc.) could not be moved directly to the JLTV. Second, there were power conversion issues from alternating current (AC) to direct current (DC) and powering the FDC while moving. Third, there was not a shelter available for the JLTV. Through creativity and collaboration with our maintenance team and the JLTV Field Service Representatives (FSRs), 2-77 FA overcame each problem to produce a highly functional JLTV FDC.

The first problem, creating a functional space to execute fire direction, was the most time intensive to solve without a conversion kit. We installed the radio stack utilizing the existing rail system, bolting it to the JLTV for safety and increased security. The radio stack was secured using two bolts and repurposed bow mounts from the Light Medium Tactical Vehicle (LMTV) and tied directly to the rail system with a bracket and bolt assembly (see images 1, 2 and 10). We utilized the existing bench and side support system from the HMMWV to create a bench in the JLTV for the FDC section to use as troop transport as well as a seat while conducting FDC operations. The bench utilized the pre-existing rail system to bolt directly to the JLTV. Additionally, the side support system was installed utilizing the existing holes in the JLTV to fasten to it (see images 9,10 and 13).

The installation of the table storage system was a challenge. The table allows the section to have a suitable workspace and mount the AFATDS for operations while moving. Since the storage table is shorter than the wheel well, one bracket was made to fasten the table to the side rail system and another bracket was made to secure the table to the bed of the JLTV. We used additional tie downs to further secure the table to the JLTV (see images 10, 11 and 12). These modifications replicated the setup used in the HMMWV, but with the larger bed of the JLTV, it actually created a larger space for operations and storage.

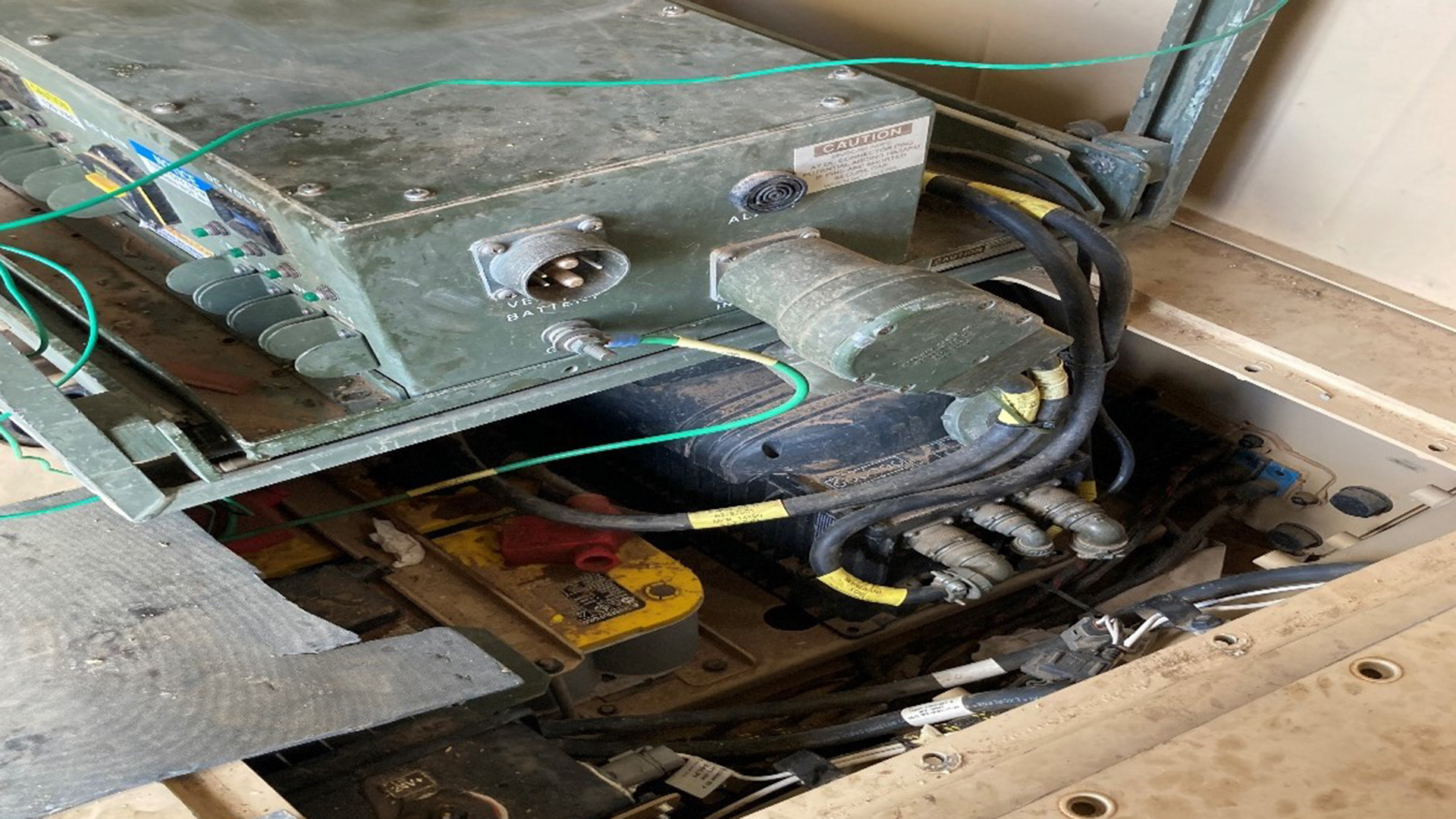

The second problem was the most complex: overcoming the power conversion issue while enabling FDC operations on the move. We utilized the JLTV auxiliary battery compartment to mount and fasten an inverter to the JLTV frame. The installation included bolting the power inverter to pre-existing holes to secure it and prevent damage while moving. Additionally, the AC/DC converter was installed on the bottom of the radio cage. This allowed the FDC section to monitor the battery voltage and state of charge, enabling the proper conversion from AC to DC power (see images 3, 4, 7 and 8). We next installed a power supply cable that enabled power to be routed from the JLTV to the inverter/converter. The power cable was modified from preexisting W69 cable to support the electrical 24V hook-ups located on the JLTV. This enabled the FDC to power all radios and radio mounts from the rear of the JLTV while moving (see images 3 to 8 and 14). This process took some coordination with the JLTV FSRs and the maintenance electricians to ensure no components were damaged prior to execution. This substantial breakthrough ultimately resulted in a highly functional mobile FDC.

The third problem was the least complex but no less challenging: how to provide cover for the FDC to enable noise/light discipline and protection from weather effects. The two-seater JLTV did not come with a bow/tarp kit during fielding. To overcome this, we repurposed a damaged set of LMTV tarps and bows to create the shelter. The process included creating 10-inch steel pole adapters to hold the bows in place on the JLTV frame. Our maintenance team shortened the cross-members for installation to create a sturdy cage. After measuring the bed, the old tarp was cut to length, placed over the bows and stitched with cord to increase the overall strength. The organic rubber fasteners were used to fasten the tarp to the bows. Lastly, two independent CGU1Bs 5,000lb straps were used to hold the bows together during the installation (see images 9, 10 and 13). This resulted in a shelter that looked very similar to the HMMWV but was wider and taller.

With all three problems solved, 2-77 FA rigorously tested the new design during its collective training in preparation for NTC. It passed all road tests over the rough Fort Carson terrain including steep hills (both ascending and descending), improved roads at speed and off-road, rocky terrain. We took the design to NTC with one battery using the JLTV FDC, the other batteries using the M-ATV FDC and our battalion FDC using a M-ATV and HMMWV mix (we weren’t fielded enough JLTVs to replace our entire HMMWV fleet). At NTC, the JLTV FDC outperformed the M-ATV FDCs used in the other batteries. In all metrics, the results indicated that our modifications to the JLTV enabled the FDCs to operate as good as, and in many cases better than, both the legacy HMMWV FDCs and the temporary M-ATV FDCs. They had more consistent and reliable communications, efficient workspace and better noise and light discipline than both the M-ATV and the HMMWV. This became the battalion standard, and after NTC, we implemented it across all batteries. A year later, we exercised a JLTV FDC pure formation at the Joint Readiness Training Center (JRTC). Again, the JLTV demonstrated its superiority to the HMMWV and M-ATV enabling a very successful JRTC rotation.

As the Army continues to roll out JLTVs, this article offers a solution to converting it into an FDC until conversion kits, or a new JLTV FDC kit, becomes standardized and available for installation. I hope you take this article not as an indictment on the modernization process but rather a credit to the ability of Soldiers and leaders to adapt and overcome friction to meet mission requirements. The JLTV is the new HMMWV, and while the initial introduction to our brigade did not provide the necessary equipment for a seamless transition, with mostly pre-existing equipment, we were able to convert it into the effective tool it was designed to be: a lethal FDC capable of providing timely and accurate fires.

Authors

MAJ John Meier is currently the Chief of Fires for Security Assistance Group – Ukraine. He served as the Battalion S3 and XO for 2-77 FA from 2021-2023 during the transition from an Infantry Brigade Combat Team to a Stryker Brigade Combat Team at Fort Carson, Colorado.

LTC Adam Ropelewski is currently the Senior Fire Support Trainer at the Joint Multinational Readiness Center in Hohenfels, Germany. He served as the Battalion Commander for 2-77 FA from 2021-2023 at Fort Carson, Colorado.

SFC Michael Limpert is currently the senior 13J Trainer at the Joint Multinational Readiness Center in Hohenfels, Germany. He served as the 2-77 FA Digital Master Gunner and BN FDC NCO from 2021-2023 during 2SBCT’s transition from an IBCT and was largely the impetus in making the FDC conversion successful.